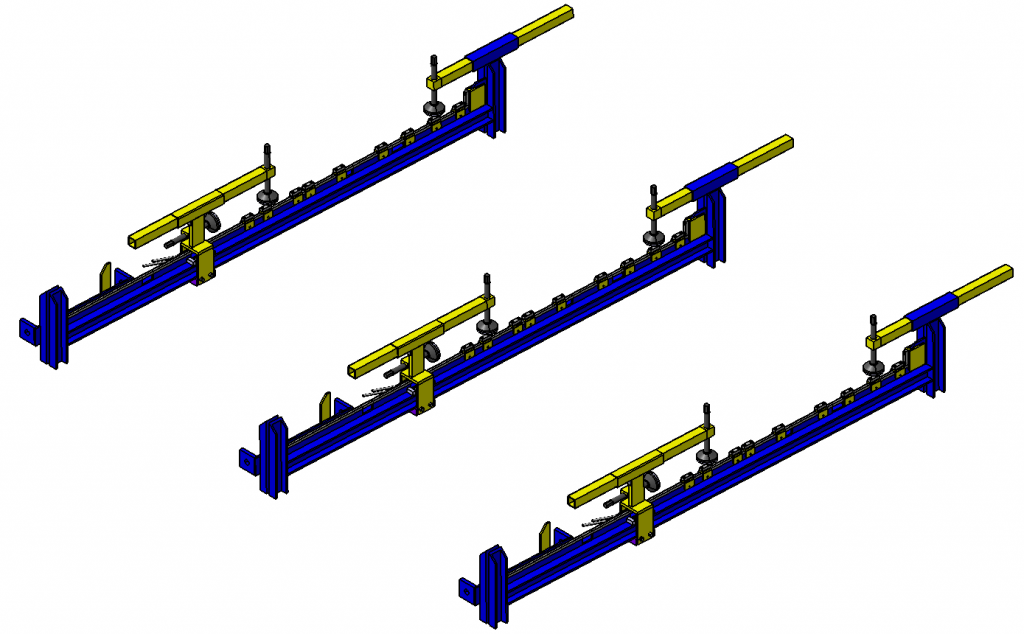

CARAVAGGIO SIDE ASSEMBLY AND WELDING TEMPLATE

Customer : Hitachi RailENGITECH has designed and built a "CARAVAGGIO SIDE ASSEMBLY AND WELDING TEMPLATE IN ESAB" installed at the HITACHI RAIL plant in Reggio Calabria.

Specifically, the design of the template was carried out to assemble the end sides of the Caravaggio order on an ESAB portal, that is:

- Modification of the existing placement that allows the assembly and welding of the end sides

For the modification of the existing assembly and welding equipment installed on the ESAB platform, a system of supports and removable stops for the new configuration has been designed.

The template made allows both straight and reverse welding, for this purpose it has been provided that:

- In the reverse configuration (rail upwards) the extrusions rest on the new stops and are blocked by the existing fixing systems already supplied.

- In straight configuration (rail downwards) the rails rest on the old stops and the body of the extrusions on the new stops, suitably spaced on the existing structure.